Photographing on the Foundry Floor

I recently had the opportunity to produce some commercial/brand photography for Columbia Steel Casting, Co. in Portland, Oregon. Columbia Steel is a storied company that has been in continuous operation at the same 86 acre location for the last 117 years. They produce cast wear parts for customers in heavy industry all over the world. I got to photograph the foundry operations on a particularly busy night when they were doing multiple pours for multiple furnaces.

The process starts with melting down 10 tons of metal alloy in an arc furnace. Once the molten metal comes up to temperature (> 2,700 degrees Fahrenheit) the furnace is tapped and the molten metal is poured into a laddle suspended from an overhead crane. From there, the crane operator and the technicians pour the molten metal into molds that are made out of sand and clay to form the parts.

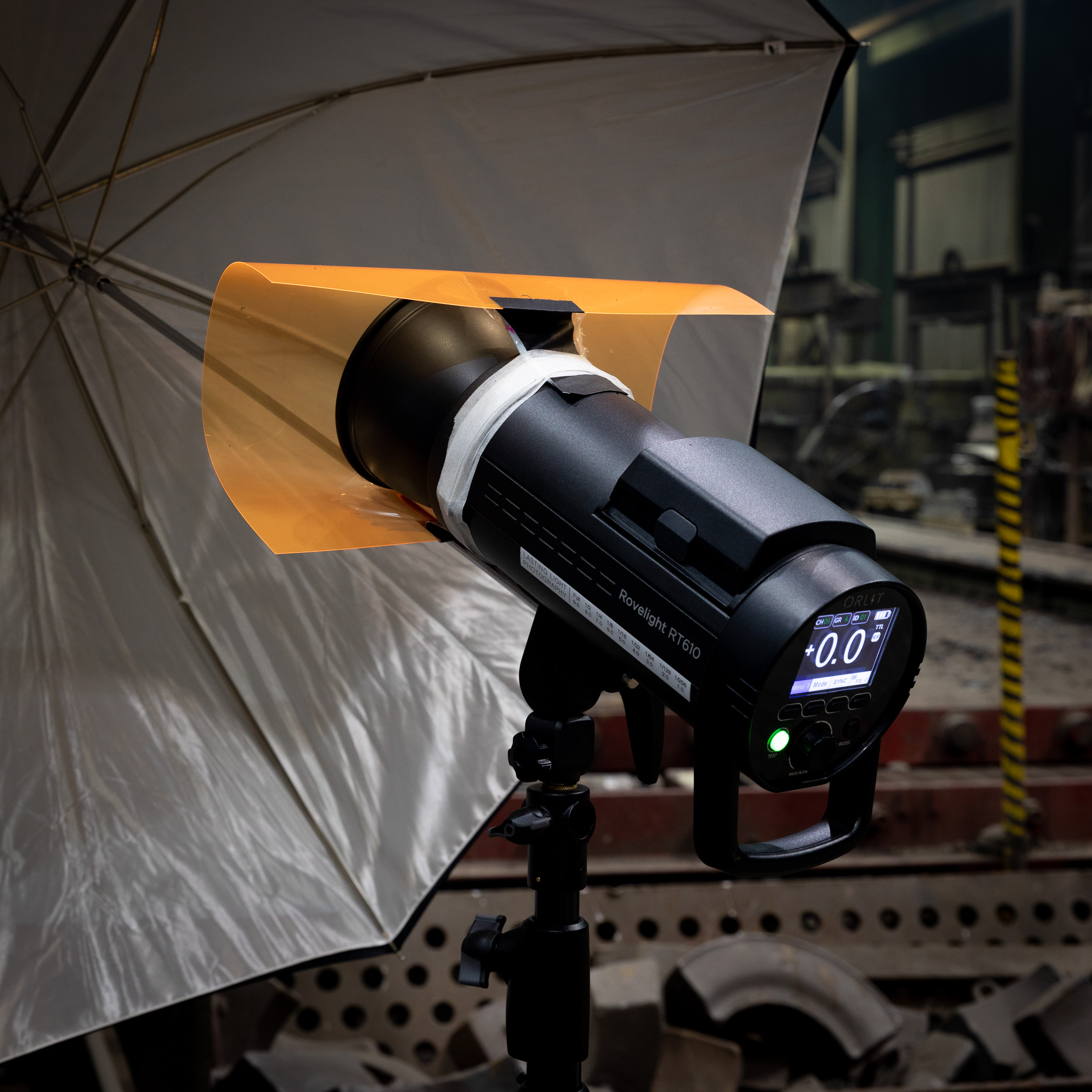

The photo shoot started at midnight (they operate a graveyard shift when off-peak electricity rates are lower) and ran until about 4:30am. The ambient light in the facility was relatively low with overhead mercury vapor lights in the foundry. For some of the shots, I used a strobe and umbrella gelled to CTO in order to match the color temperature of the molten metal and glowing smoke.

To see the full set of images, you can go to:

https://lastinglight.pixieset.com/columbiasteelcastingco/

One nice bonus was that the images were featured in the Sunday Business section of the Oregonian newspaper in conjunction with a feature story about the labor shortage and challenges with recruiting workers in the current economy. The full story can be found on Oregon Live and a copy of the print edition is included below.